Ready to see what we have coming?

Lynx Defense will release some new things soon. Let us deliver them right to your inbox!

Lynx Defense will release some new things soon. Let us deliver them right to your inbox!

We may earn revenue from product links on this page and participate in affiliate programs. Learn More ›

Here’s the scenario: you have a pistol from the prehistoric era that you want to bring to the modern age and have the slide milling for an optic.

So naturally, you set out to find the best slide milling company because she’s an old gal, and you still want it done right at a fair price.

Well, we put one to the test so that we could report back our findings: C&H Precision.

Here’s how the process was and went for me, and I have to say *spoiler alert* I highly recommend C&H Precision for any of your slide milling needs.

I thought this process was going to be more difficult than it was. First, I knew I had an original P365 dying for an optic.

It’s a great gun, but with all the available micro pistols with optics, this one needed to be updated.

So now it was time to make a few decisions on what would come of my P365.

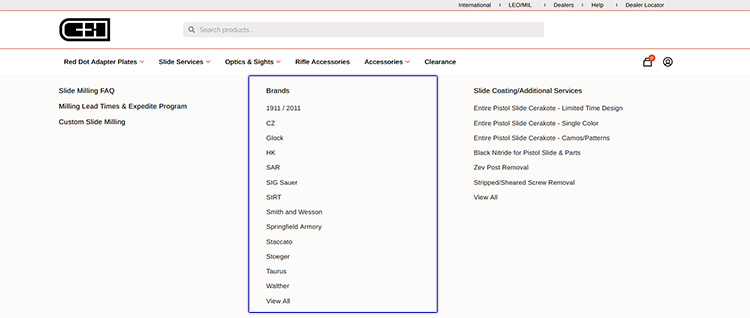

C&H does a great job of making this process as easy as possible. Since you already know what brand gun you plan to send they make it easy to get directly to the options.

For example, if you want to have your Glock slide milled you just need to clock on the Glock brand category and located which model you have.

If I had one criticism of the process, it would be the next step. Once you select your brand of pistol, it isn’t immediately clear, especially on uncommon models, where your gun falls.

If you have a Glock 43x or a 48, it’s pretty simple. There is a specific product for you to click; however, if you have a Glock 19, you must go into the Glock slide milling product page and read through the product description to know you are in the right place.

However, the process gets much better from there, but the decisions don’t get easier!

Click Here to Start your Slide Milling Project with C&H

From the start, it’s almost required to either have the pistol red dot in mind you want to add to the gun or the best bet is to have the optics purchased already.

It’s not required, but a nice touch from C&H is if you include your optic or purchase one from them, they will install it for free.

It was an easy decision for me because I’m always searching for the best pistol red dot optic to keep our content up-to-date and have the best information.

So, the C&H EDC pistol optic was the obvious choice since I have yet to get a good hands-on evaluation of the optic.

Now that the optic was picked and a done deal, what else should we choose? After all, C&H has tons of options for your slide.

You can have the slide milled for an optic but also mill cocking serrations, windows, or pockets. You can have them turn your busted ole’ Glock 19 into the Gucci Glock of your dreams!

I didn’t get too crazy on this P365, just the optics cut and a fresh cerakote to freshen up this dated everyday carry pistol.

Once I placed my order, I dropped the slide in the mail, and it only took a few days to arrive at their Georgia facility.

I didn’t have to hawk the tracking because as soon as they received the slide, I got a phone call from C&H to confirm they received my slide.

If you are like me, I ignore numbers I don’t know, so you may want to save their phone number ahead of time so you don’t ignore the call.

But if you forget to do that, it’s no big deal. They will leave a message. The nice thing is they call to confirm they received it and confirm the order and make sure it’s how you want it before they start.

I called back and confirmed everything and it was off to the races. Not even a week later, I received a shipping email that the slide was on the way back to me.

C&H has a great policy: 4 Weeks or less, or your next milling is FREE!

I thought this was a mistake because that was far too quick to be true, but it was real. Ole’ faithful was on her way back, topped with a new optic and fresh cerakote job.

The slide was shipped back quickly and I was extremely pleased with the expedited shipping. Since I got the C&H EDC red dot with it, the box included the red dot box, but the red dot was already installed.

All I had to do was pop in the included battery, and I was off to the races. The cerakote job was fantastic, and the witness marks for the optic installation were a fantastic touch.

This was a top-notch job done by someone who paid close attention to detail. Reassembling the slide was nothing more than what you would do after cleaning the pistol, which was extremely easy.

Things happen, so you probably wonder what guarantees C&H has and why I should trust them over trying to go local.

C&H Precision does not require customers to send in their optics for slide milling, but it is heavily recommended. Any slide sent in with an optic will have the optic mounted at no additional charge.

If you choose to supply your slide without an optic C&H Precision cannot guarantee the slide cut will work for your optic due to the tight tolerance of our milling and the tolerances in manufactured items.

If any issue is found with a slide milling order, minus slide finishing, please contact C&H Precision through our contact portal and have photos and detailed descriptions ready. We may require the slide and optic to come back to the shop for inspection before determining if anything is defective with the cut.

C&H Precision will guarantee your slide’s finish up to 1 year from ship date if it is determined to not be within the realm of normal wear and tear, excessive use, negligence, or purposeful damage. Holster wear is considered normal wear and tear and is not covered under this warranty.

From the C&H Slide Milling FAQ Page

One of the many reasons sending the slide to C&H makes sense is from the stories I have heard about when they have messed up, which is almost as important to me as how few times a company messes up.

I have heard independent stories of how they messed up a slide during milling. Since they have great relationships with gun manufacturers, they were able to replace the slide and even get matching serial numbers.

Your local slide milling company can’t match that, and while they may do great work, I want to ensure the warranty process, if needed, can handle something like this.

Overall, I highly recommend using C&H Precision to do your slide milling. The process was smooth and the work that was done was fantastic.

The communication was A+ and the turnaround was wicked fast. Not to mention the price is extremely reasonable. You can have a whole new slide for right around the $150 mark and that’s extremely hard to beat.

Click Here to Start your Slide Milling Project with C&H

Not every slide is manufactured the same. The primary determinant of whether a slide is suitable for optic milling is its internal parts, especially the striker or firing pin safety plunger.

Should the milling for an optic placement interfere with the functionality of these internal components, then the slide cannot be modified to accommodate a red dot.

The feasibility of direct milling for an optic depends on the specific optic-ready cut of the pistol.

Modify the slide for compact pistols equipped with an RMSc optic-ready cut to allow the direct mounting of Holosun models 407k, 507k, EPS, and EPS Carry without requiring an adapter plate. Additionally, for certain slides with an RMSc cut (such as the G43x, G48, and P365), we can perform modifications to enable the direct mounting of the Trijicon RMRcc.

For Sig slides that originally have the older Romeo1 optic-ready cut, C&H can upgrade to the Romeo1 Pro cut, making them compatible with our Sig adapter plates. This cut can also be altered to accommodate the RMR footprint, allowing for the direct attachment of optics with an RMR footprint. They also provide services to mill RMR holes in slides with the Romeo1 Pro cut that do not already feature these holes.

For the Walther PDP, they can convert the original 1.0 optic-ready cut to the more versatile 2.0 optic-ready cut, which supports both our PDP2.0 adapter plates and the direct mounting of the Holosun SCS-PDP optic.

These specialized modifications enhance the compatibility of your firearm with a broader range of optics, eliminating the need for adapter plates in many cases.

Concealed Carry Insurance

Protect yourself and all those who carry concealed in your house.